Why Trevi Test ?

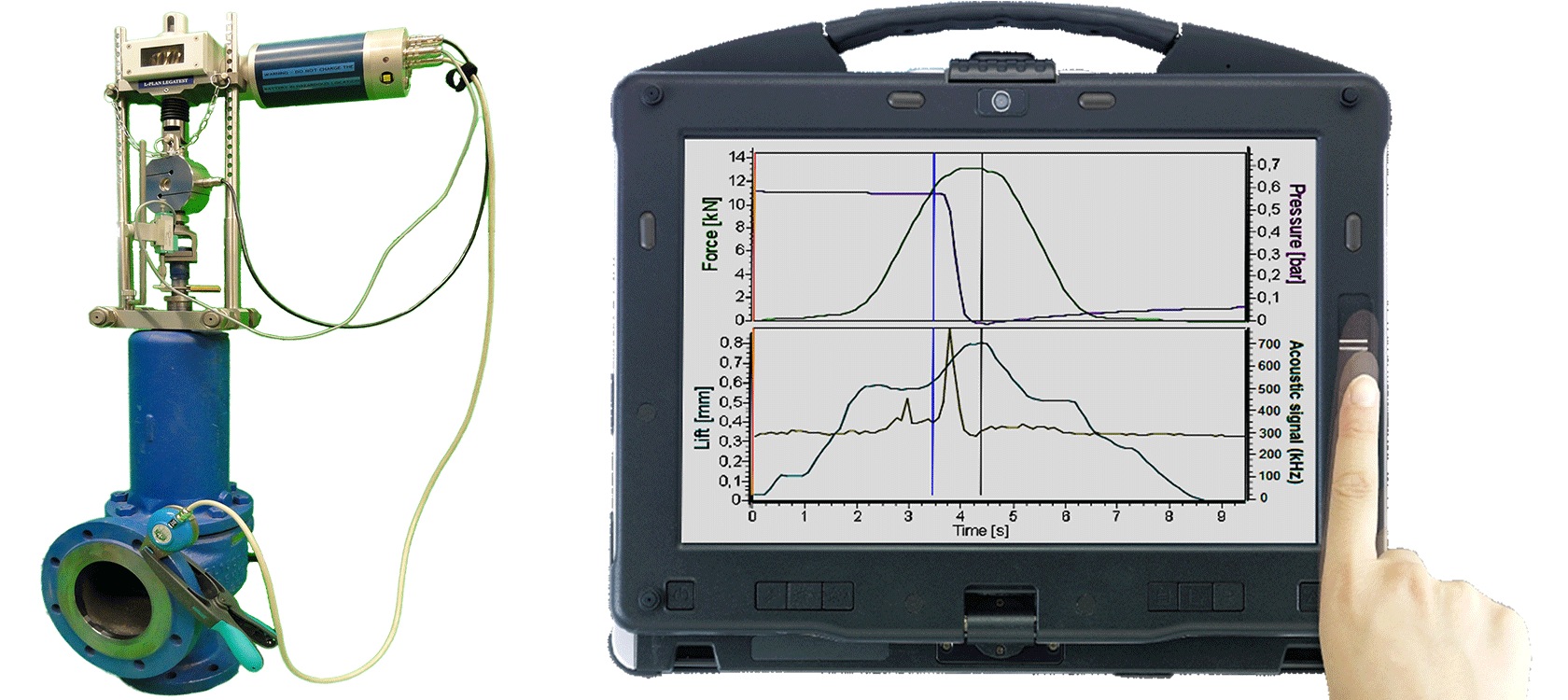

ONLINE SAFETY VALVE TESTING :-

Safety valves are crucial components installed on process

pressure equipment to prevent excessive pressure buildup, which can occur due

to various factors such as faulty process operations, external fires, and other

hazards. These valves serve as a last line of defense when all other safety and

control devices fail, releasing excess pressure and safeguarding the pressure

equipment from potential explosions. Their proper functioning is essential to

protect both human life and property.

If pressure safety valves fail to operate effectively, it

can lead to severe damage to vessels, exchangers, boilers, and other equipment.

Therefore, it is crucial to regularly maintain and test pressure safety valves

and relief valves to ensure their optimal performance.

One of the most critical aspects of maintaining the

functionality of safety valves is periodic testing. While traditional testing

methods exist, on-line testing, also known as on-site, in-situ, or under

operation pressure safety valve testing, provides more accurate results. This

method involves testing safety valves in real process pressure equipment

operating conditions, where the valves are exposed to factors such as process

system temperature, accumulation and flow capacity, compliance with back

pressure, and other influences related to the performance of the process

pressure equipment.

By considering these actual operating conditions, the

results obtained through on-line testing are more precise compared to classical

testing methods. However, it is essential to use appropriate devices and

methods that account for all the factors affecting the accuracy and reliability

of the results, especially in challenging industrial environments.

Our device fulfill

these necessary conditions and currently hold a top position worldwide.

Benefits of Online Safety Valve Testing

- No interruption to plant production during testing.

- Diagnose safety and relief valves that require maintenance while the plant is running normally prior to scheduled shutdowns.

- Reduced time needed to commission the plant after shutdown.

- Reduced fuel costs with no need to raise system pressure.

- Only valve that require an overhaul need to be removed from the line.

- Welded in valves can be adjusted without costly removal from the line.

- Multiple test and resetting of valves within a short time scale.

- No need for temperature compensation to set pressure.

ONLY DEVICE TO PRODUCE THE BLOW DOWN RESULTScontact now

We produce High Accuracy results along with the special safety features.

After the valve set point is reached, several limitations turned down the spindle in start position. Special sensor measure the device spindle position.

Our system is Approved by

0